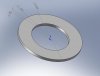

1) Material type

-aluminum (type is not as important as obtaining what ever will work the best)

-you would supply the material

-the material that these mate to are made out of 6061

2) quote a quantity 100 and a quantity of 500

3) Break sharp edges, Blue Anodized finished

4) Currently I just need an estimate on these I am not sure if this project will pan out or not.

More Info:

These are bead locks for aluminum RC wheels. I would be doing further drilling and milling on these. I am thinking these could be cut out by a water jet but I am interested in the most efficient way. I am not familiar with what kind of finish a water jet leaves on the edge. If you have a better way though let me know. Tolerances should be +/-.003. The surfaces need to be an acceptable finish, fairly flat and look good after anodized. The .100 thickness should be close but sheet stock close to that thickness would work. I have made these previously using a manual lathe and 2.25 round stock. I would drill a hole as deep as I could and than part them off. This seemed time consuming and wasted a lot of material. A CNC lathe however would be a lot faster.

If you need more info contact me at jake@motoworxracing.com

thanks

Jake

-aluminum (type is not as important as obtaining what ever will work the best)

-you would supply the material

-the material that these mate to are made out of 6061

2) quote a quantity 100 and a quantity of 500

3) Break sharp edges, Blue Anodized finished

4) Currently I just need an estimate on these I am not sure if this project will pan out or not.

More Info:

These are bead locks for aluminum RC wheels. I would be doing further drilling and milling on these. I am thinking these could be cut out by a water jet but I am interested in the most efficient way. I am not familiar with what kind of finish a water jet leaves on the edge. If you have a better way though let me know. Tolerances should be +/-.003. The surfaces need to be an acceptable finish, fairly flat and look good after anodized. The .100 thickness should be close but sheet stock close to that thickness would work. I have made these previously using a manual lathe and 2.25 round stock. I would drill a hole as deep as I could and than part them off. This seemed time consuming and wasted a lot of material. A CNC lathe however would be a lot faster.

If you need more info contact me at jake@motoworxracing.com

thanks

Jake

Attachments

Last edited: